Raif Karaahmetoğlu

Software Control Developer

I am a dedicated mechatronics engineer with a deep commitment to the core pillars of mechatronics: mechanical design, control systems and software development. My expertise includes the design of complex mechanical systems, the development of advanced algorithms and the implementation of sophisticated control strategies. I enjoy my ability to adapt quickly and continually expand my knowledge to integrate the latest software design principles and deliver innovative, high impact solutions.

Projects

Return Back

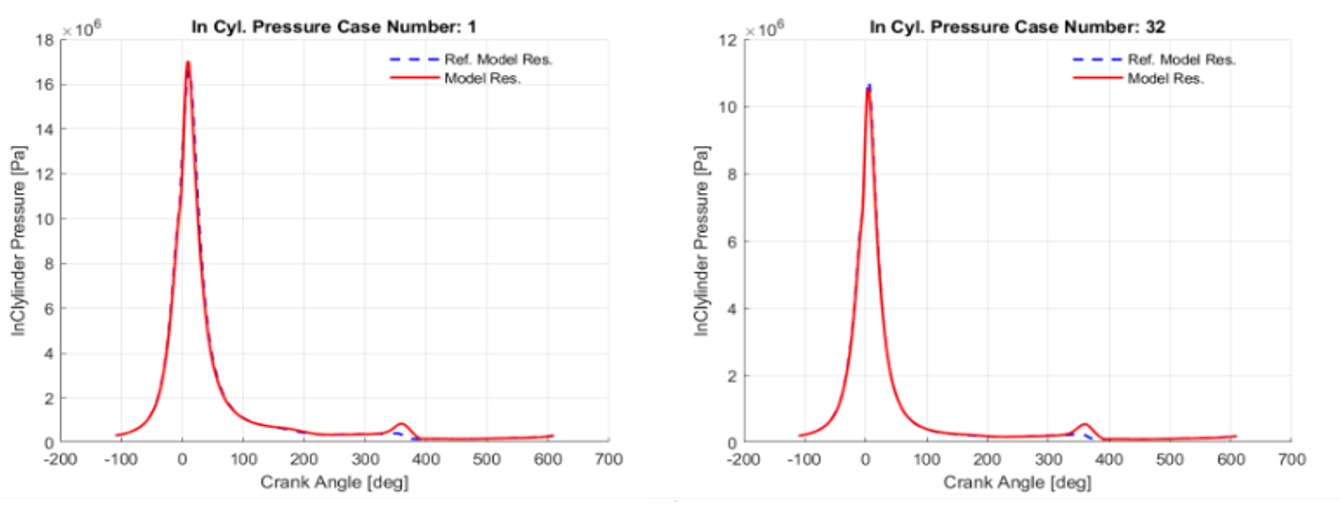

ICE Model

The internal combustion engine model was created to develop control algorithms. This simulation model needs to be both accurate and fast to meet performance and real-time calculation limits on HIL systems. Therefore, a zero-dimensional modeling technique was chosen to ensure a representative and quick simulation model. In this model, engine operational states can be determined at each sample time or crank angle used as the sampling rate. The model includes various equations: kinematics to calculate positions of slider crank mechanisms, fluid dynamics for air flows related to the cylinder, turbocharger, and intercooler components, and thermodynamics for in-cylinder calculations, especially for pressure and temperature states due to combustion. Building such a diverse model requires a solid foundation in mechanical engineering principles like fluid dynamics, thermodynamics, mechanism design, and even chemistry. Basic and detailed combustion models were developed, such as the Wiebe and Constien combustion models. The Constien model was highly accurate for mimicking the diesel combustion process, especially for multiple injection strategies. Critical states like in-cylinder pressure and temperature were captured with high precision while still providing real-time capabilities. The parameter identification process was done using different algorithms, such as genetic algorithms, simulated annealing, or simple gradient-based algorithms for linear-like systems. The engine is fast and accurately represented by the model built and tuned. This model showcases the detailed engineering work involved in its creation. It combines various mechanical engineering principles and advanced algorithms to create a robust and versatile tool. As a result, this engine model helps in developing advanced control algorithms, improving engine performance and efficiency. The process of building and refining this model highlights the importance of interdisciplinary collaboration and the pursuit of excellence in engineering.

Skills

Contact Me

© 2025 All rights reserved.

Thanks for visiting! Feel free to connect with me.