Raif Karaahmetoğlu

Software Control Developer

I am a dedicated mechatronics engineer with a deep commitment to the core pillars of mechatronics: mechanical design, control systems and software development. My expertise includes the design of complex mechanical systems, the development of advanced algorithms and the implementation of sophisticated control strategies. I enjoy my ability to adapt quickly and continually expand my knowledge to integrate the latest software design principles and deliver innovative, high impact solutions.

Projects

Return Back

GEM Model

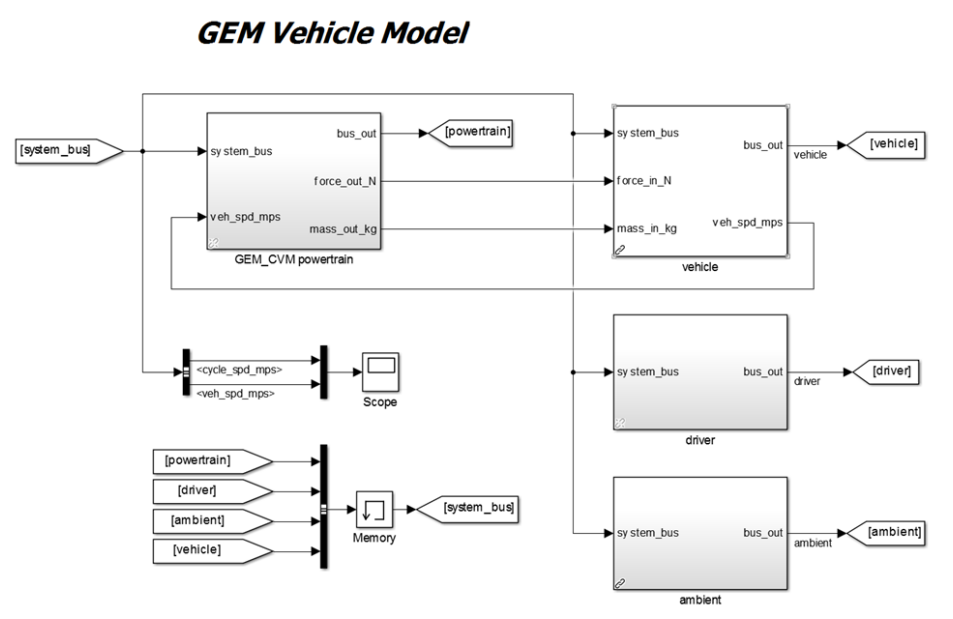

The GEM model is a vehicle simulation model used for estimating greenhouse gas emissions and fuel efficiency performance of specific aspects of heavy-duty vehicles. The GEM model, developed by the EPA in the USA, was to be integrated with Puma/IGEM 2 software to run on a power pack test bench in real time. GEM was intended to represent the real vehicle in the test environment. Initially, GEM was developed for offline simulation only, with no real-time application of the model. The first task involved adapting the model parameterization process to the PUMA/IGEM2 workflow. This was followed by the adaptation and refactoring of the GEM vehicle models to fit the workflow. It was determined that a pure offline simulation was needed to estimate the cycle performances for the respective test runs, which are sorted according to the energy consumed by the vehicles. The parameterization process and the structure of the model were investigated. After analysis, it was decided to wrap the parameterization process with the codes that run the offline simulations. In this way, the parameters would be used both by the offline simulations for sorting the cycles and by the real-time models when the final real tests were run. The GEM model structure contained unnecessary components for the real-time test, as the power-pack elements are real units. Therefore, the model structure was simplified. Model inputs and outputs were added for information exchange with real components and test bench management. Additionally, functions were developed for seamless operation, such as bumpless transfer to allow the model to update its parameters during the transition from one cycle to another, manual operation modes, and safe simulation mode switching algorithms. The GEM project was completed and delivered successfully. New methods for integrating the compiled offline models along with Matlab scripts were introduced, enabling colleagues to use the same methods to integrate their legacy codes into simulation models. The methods used contributed to the competence of the team. Additionally, the bumpless transfer method, which allows parameters to be updated on the fly, was implemented as the first example of such an algorithm.

Skills

Contact Me

© 2025 All rights reserved.

Thanks for visiting! Feel free to connect with me.